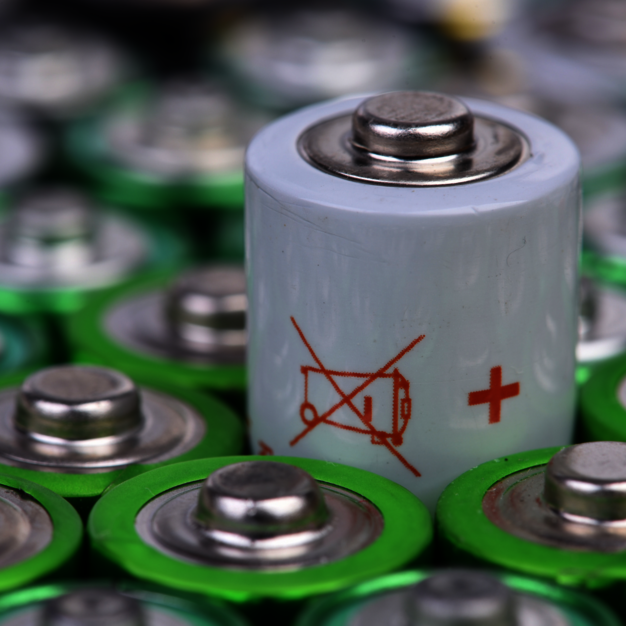

Cutting battery foils

Battery foils, i.e. coated and non-coated non-ferrous metal foils, are a key component of modern rechargeable batteries that form the basis of electromobility. The quality of the cutting edge has a direct influence on the performance and reliability of the battery cells. NEUENKAMP sees itself as your partner to achieve the challenging requirements for slitting battery foils.

The challenges:

- Sensitive materials: Battery foils, usually made of aluminium, copper or plastic, are very sensitive in many cases.

- Precision and tolerance: Maximum precision and tight tolerances are essential, as the slightest deviations in cutting quality can lead to undesirable electrical losses or short circuits.

- Versatile production requirements: The range of requirements for processing battery foils can be very broad and includes varying cutting widths, as well as process data acquisition including documentation.

- Dust and contamination: The slitting process can cause dust and impurities that are undesirable in a clean working environment.

- Wear and service life: Cutting tools must be durable and have a sufficient service life to ensure maximum availability of the production systems.

- Production speed: High production speeds are often necessary to fulfil market requirements.

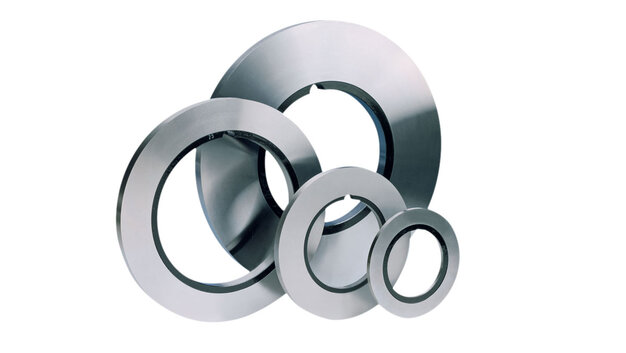

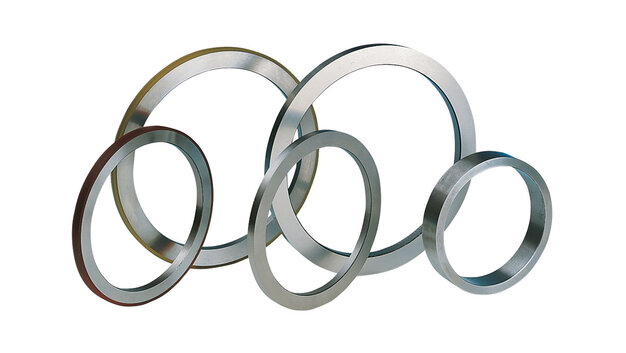

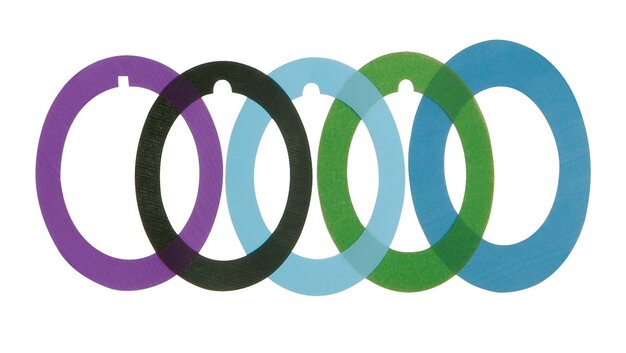

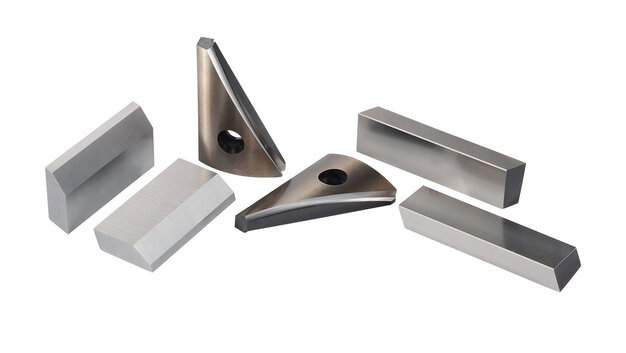

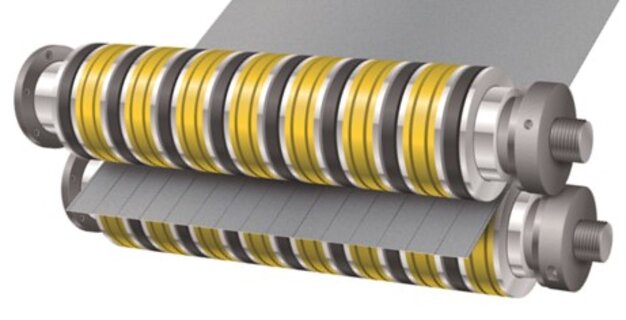

NEUENKAMP offers all components for the various slitting processes (circular shear cut, razor blade cut and shear cut): such as suitable knives in different material qualities, special collars as well as adequate bottom knives and knife holders.

YOUR ADVANTAGES:

- circular knives, knife holders, cutting cassettes and robot slitting systems from a single source

- smooth, clean cutting edges and narrowest cutting width tolerances

- long knife service life for greater cost-effectiveness

- comprehensive service: technical consulting, seminars & training, kaizen analysis, slitting laboratory

- regrinding service

Please do not hesitate to contact us for further technical information:

E-Mail: info@neuenkamp.de

Phone: +49 (0)2192-9 36 85-42

Production automation using knife-making robots in strip processing simplifies storage and handling.

However, this innovation places special design requirements on the tool set.

Neuenkamp has taken on this task and is today the leading supplier of automatic assembly systems. Use our experience for your new technologies.